Benchmarking materials: How can we make durable and affordable low-emission furniture?

Climate Pioneers No. 10 compares five materials and peeks into the future of furniture.

Receive stories and surprises about climate solutions directly in your inbox.

Dear Climate Pioneer

Do you want to create a carbon negative furniture product together? Come on a quest to find out how. For the sake of benchmarking, we’re assuming to make a bench.

For this special issue I teamed up with my brother David, an industrial designer, to compare materials and explore the future of furniture. We look at four questions:

What’s the problem with furniture? Global and user perspectives.

What is the impact of materials? A comparison of 5 materials.

Who is doing resourceful furniture design? A list with 21 examples.

So how can we make it? A first conclusion and 6 ideas.

If you enjoy the content, consider forwarding it or becoming a member to access past and future publications anytime.

Thanks!

Sam & Dave

1. What’s the problem with furniture? Short life cycles, indoor pollution and hard to get rid of.

Cheap and disposable furniture fit well into flexible lifestyles. On the other hand ‘fast furniture’ is polluting the environment not just at large, but also at home:

Greenhouse gas emissions from overall material production increase.

The average piece of furniture generates around 47 kg of CO2e.

Chemicals like formaldehyde in furniture pollute the air indoors.

Furniture piles up into millions of tons of waste in landfills.

We also asked a few people what they find frustrating about furniture. Here is what they said:

No furniture is cost-friendly and robust at the same time.

The cheaper it is, the more vulnerable.

Getting the right size can be difficult.

Keeping it without scratches and new looking.

Hard to resell or dispose (especially larger furniture).

It seems we’re in a short-cycled flatpack furniture trap. How to get out of it? Is it possible to make more durable and healthy goods at competitive prices and convenience? To answer this question we start off with looking at materials. In the next section we evaluate five widely used materials.

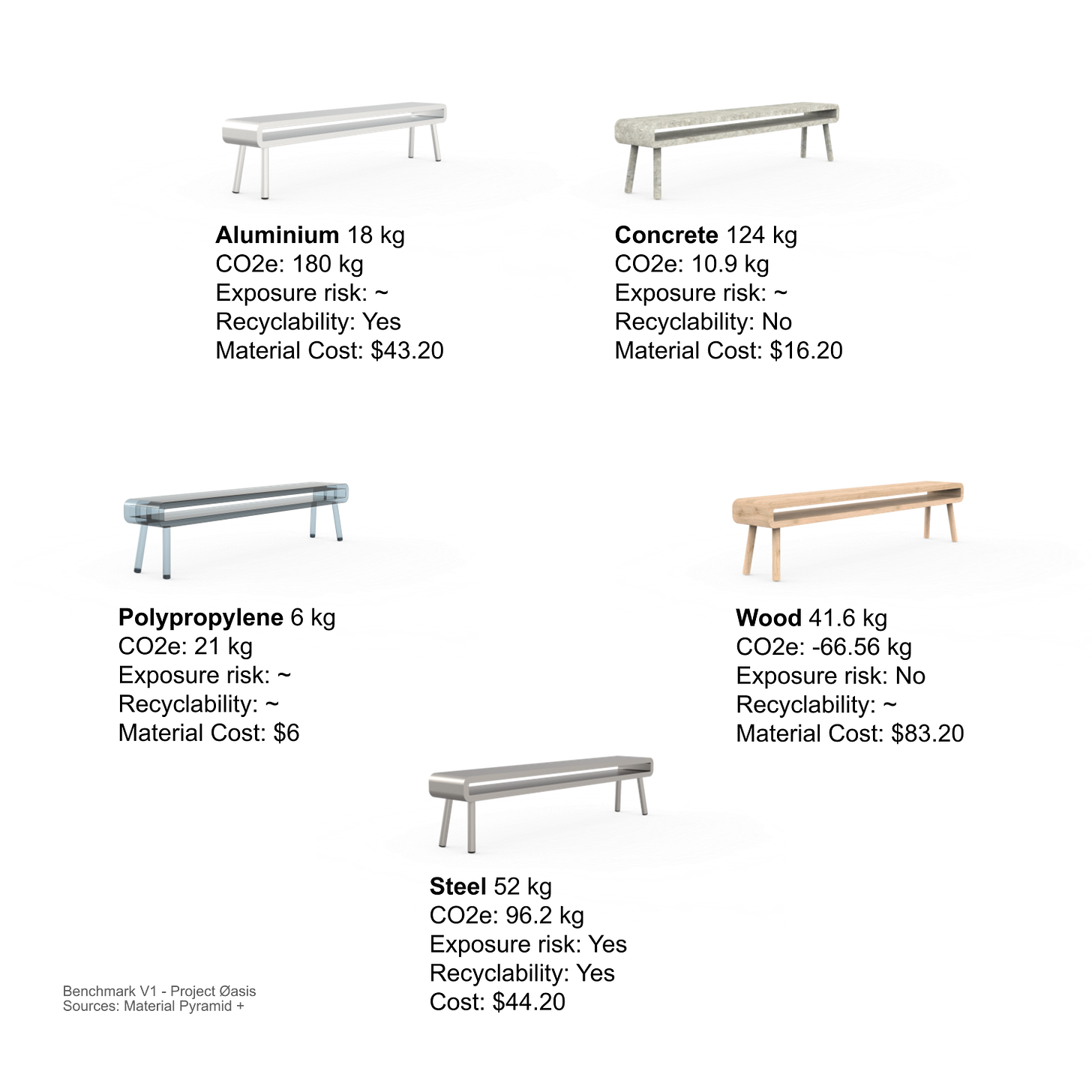

2. What is the impact of materials? A comparison of five common materials and their embodied carbon footprint, exposure risk and recyclability.

Which one is your favourite bench material? Vote for it.

Our estimations on five common materials are based on the material pyramid, inputs from Viola Hasani and Jonas Scheyrer from Worldwatchers and various other sources as stated below.

Aluminum is at the top of the pyramid with over 10 kg of CO2e per kilo of product. The high number is largely dependent on the type of energy used in manufacturing. Smelters running on hydropower can reduce emissions to around 2-4 kg of CO2e. On the bright side aluminium can be recycled indefinitely and thereby save 90 percent of the energy use and reduce the footprint by a factor of 10 to 18 kg CO2e. Exposure limits exist in manufacturing environments. Aluminium is currently priced at about $2.40/kg. Our bench needs 18 kg of material resulting in $43.20.

Concrete for lightweight elements emits 202.3 kg CO2e per m³. Globally concrete generates roughly 8% of CO2 emissions! Plus its excessive need for sand destroys landscapes. Companies like Carbonbuilt, CarbonCure or Neustark are improving concrete’s carbon footprint. Concrete is toxic in occupational exposure, but performs also as an anti-allergic surface at home. Concrete can be recycled and reused, but currently the vast majority is dumped in landfills. Concrete costs $300 per m³. At the bench’s volume of 0.054 m³ this would cost $16.20 and 10.9 kg CO2e.

Plastic is made from fossil fuels. Polypropylene has a carbon footprint of 3.5 kg CO2e per kilo. Our bench can be made with 6 kilos of polypropylene, which would translate into an embodied carbon footprint of 21 kg. Currently less than 10 percent of plastic is being recycled. With recycled PP we could half the footprint. Also, with PDK, a new product is on the horizon that can be recycled without losing its strength. In terms of toxicity, polypropylene is usually considered safe for humans. Polypropylene prices are currently at about $1000 per ton resulting in $6 for our bench.

Steel emits on average 1.85 tons of carbon dioxide per ton. For the volume of our bench we would need 52 kg (7850kg*0.0067m³) of steel that embodies 96.2 kg of CO2e. Long-term exposure of steel can be harmful to humans. Steel is 100 % recyclable and frequently done so. With recycled steel the bench’s CO2e footprint decreases by a factor of 2. A ton of steel is currently about $850 per ton resulting in a material cost of $44.20.

Wood from forests that are replanting trees can sequester CO2: 1000 kg of wood absorb 1600 kg CO2e from the atmosphere. Our bench would need 41.6 kg of wood and embody -66.56 kg of CO2e. Carbon can be stored in wood furniture for about 30 years. Wood is being recycled for energy generation, paper production or wood pellets. However, decomposing wood in landfills can release methane. Except for manufacturing environments (saw dust), the exposure of wooden materials can have positive health effects on humans. Hardwood like oak costs roughly $1500 per m³/750kg, resulting in material costs of $83.20.

Besides wood, none of the compared material is carbon-neutral or negative. Of course, the manufacturing and transportation of the bench will further influence the carbon footprint. For example, in a life cycle assessment (LCA) for the wooden bench with timber from Canada manufactured in Switzerland, the net carbon emissions might switch to positive. The bench is relatively easy to build with the exception of one material. Polypropylene would need to be melt into form, depending on the electricity used that could increase CO2e significantly. We could offset the footprint. With a carbon removal cost of $100/t the material cost for a carbon-neutral aluminium bench would jump from $43.20 to $61.20.

To go further into the details of the process will be the next step. Now we want to know what’s going on in the futuristic corner of the furniture world.

3. Who is doing resourceful furniture design? 21 highlights including digital sofas and growing chairs.

What follows is a number of products, studios and startups working on exciting and sometimes weird solutions.

Alice and Gavin Munro grow and harvest chairs in their orchard. 🎋

Andres Reisinger sells furniture as digital tokens before making it. 💿

Empa researchers turn wood until it’s a formable supermaterial. 🔬

Ekoa makes wood from plants. 🌿

Feather lets you rent and swap furniture. 🛋

Forust prints wood in 3D. 🖨️

Ian Anderson shares designs of Do It Yourself objects. 🔨

Jonas Edvard made a chair with seaweed. 🌊

Merdacotta is a cow dung material for outdoor furniture. 💩

Naturloop makes panels from coconut husk. 🌴

Neolign turns wood chips into recyclable furniture. 🪑

Newlight does straws and cutlery from captured carbon. 🕸️

Opendesk forwards orders for office furniture to makers. 🚚

Pollima is launching CO2-negative furniture. 📉

Robots assemble furniture or self-assemble into furniture. 🤖

Solid wool designs chairs made of wool. 🐑

Tiptoe and Jakob Schenk make legs to turn boards into tables.🦵

UBQ materials converts waste into climate positive plastic. 🍕

Vepa makes furniture from hemp. 🌿

Wehlers took ocean plastic to make a chair. 🌊

What Design Can Do hosts over 1400 ideas to rethink waste. 💡

Which one do you like, what did we miss? Let us know via comments or the form.

4. Conclusions and ideas: So how can we make durable and affordable low-emission furniture?

After looking into five materials and industry trends it seems that the individual elements exist to make furniture that has a low carbon footprint, no negative health effects, can be recycled and is affordable. Not only must we continue the quest for materials, but also look into the manufacturing process, eventually the two are inherently bound together.

Along the way we have already found these ideas particularly interesting:

Pre-selling furniture designs online and forwarding the orders to artisans.

Designing with the afterlife in mind: easy disassembly, recycling and reuse.

Modular quality materials: long-living materials with flexibility of use cases.

Making waste available as sources for new products across sectors.

Super durable wood furniture to store carbon over decades.

Renting out as a solution to address the waste problems.

In an ideal world, resources would turn into products in a snap and disappear again into thin air as desired. What are you thinking about all this? Share your thoughts via replies, comments or in the poll.

Our grandmother often sat on a simple bench in front of the farm where we grew up. In a break from playing we would sit next to her and listen to her colorful stories. We can create stories and designs with you, get in touch: sam@projectoasis.ch

If you ever find yourself bored on a bench, you can check one of these three articles: